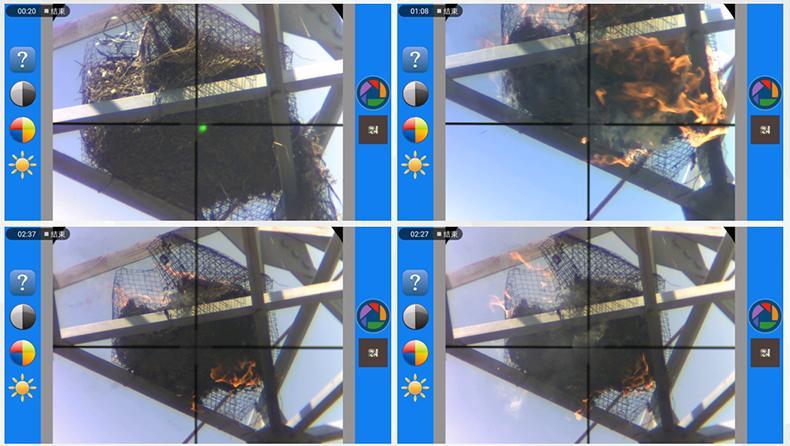

Burning process during laser removal of bird's nest

Bird's nests are often built on power grid rail towers. Branches, grass stems, wire and so on held by birds easily trigger the short connection of the charged body, resulting in tripping, and even burning the equipment. It will cause the power equipment power failure of catenary machines, causing a great impact on the normal transmission and distribution power grid. In particular, birds peck insulator string damage, and bird feces cause insulator string flashing and other circumstances, which will cause more serious power safety accidents.

At present, the ways to clear the bird's nest are: first, mainly manual cleaning by manual climbing. For small iron towers and pole frames, it is carried out by simple mechanical devices with stabbing, cutting, and burning. For the removal of bird's nest on the medium and large pole and iron tower, it is very difficult to coordinate the actual operation. Second, the traditional mechanical cleaning mode: it is not easy to be operated, which belongs to the direct contact cleaning mode. It is easy to cause electric shock safety hazards to personnel and equipment, especially hook-type, rope-type and drag-type equipment. In the outdoor actual operation process, they are easy to cause line up and hang up, forming serious safety hazards. Third, non-contact cleaning. There are more fire burning types, but the current bird nests removal in electric power network are mostly concentrated in summer and autumn, avoiding the peak reproductive period of birds. Burning of bird's nest is not only easy to cause outdoor fire risk, but also not conducive to the safety of power equipment. At the same time, in the daily maintenance and use process, it requires complex precautions. It is easy to cause safety accidents and is inconvenient for use.

Birds nesting close to the wire on the iron tower pose a risk of line trip, which can be effectively removed using laser cannon.

Nowadays, laser manufacturers have developed a bird's nest removal device (laser obstacle remover) based on laser emission. The beneficial effect of this product is that it has simple structure, stability and reliability, which can completely reduce the risk caused by manual cleaning of bird's nest on transmission lines, reduce the labor volume of workers and save costs. It belongs to the non-contact removal method and is also an extremely safe bird's nest removal method at present.